519-688-4826 |

![]() login

login

519-688-4826 |

![]() login

login

When your transportation business needs new ideas for profitable hauling, Titan is the right place to start. From the top down, Titan’s business is to solve customer problems. And, in our experience, there’s no shortage of problems to solve.

Our secret to success is close communication between Titan engineering, our production team, our dealers and our customers. Because our management and staff are all “hands-on” with your trailer from start to finish, there are no roadblocks to making changes anywhere along the line – we can fast-track any idea to give you the best possible product.

All Titan employees are encouraged to be an active part of our improvement process, to suggest new ideas even when a trailer is already in production.

Innovation makes us stronger and it makes our customers stronger, too.

FACTORY

As a custom builder, Titan has to be ready to move whenever our customer is ready to spec a new trailer. To make and keep our customer commitments, we built one of the most complete, most advanced trailer fabrication shops in the world. Our production facility handles every process from product development to finishing and testing. And, over our 30 years, we have trained and recruited an unbeatable team of tradespeople and shop professionals – people who are equal to the challenges of custom building.

Innovative “green” technologies in our new manufacturing facilities put Titan at the forefront of sustainable manufacturing practices for employee and environmental health.

Our shop floor isn’t locked into a specific production line process. Every Titan trailer goes through production with a full set of custom design prints and quality control checks, so every operator on the job knows exactly what our customer is expecting.

To assemble our extruded THINWALL™ panels, we developed our own automatic welding process. It deep welds the sides automatically, more accurately, with a more pleasing finish and 75% faster than any other available process.

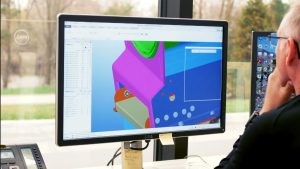

ENGINEERING

When your transportation business needs new ideas for profitable hauling, Titan is the right place to start. From the top down, Titan’s business is to solve customer problems. And, in our experience, there’s no shortage of problems to solve. Our secret to success is close communication between Titan engineering, our production team, our dealers and our customers. Because our management and staff are all "hands-on" with your trailer from start to finish, there are no roadblocks to making changes anywhere along the line – we can fast-track any idea to give you the best possible product.

WALKING FLOOR

Lightweight, long life, high performance – Titan takes pride in equipping the world's best-built custom trailers with the world's leading technology in moving floor trailer systems. Titan walking floor trailers feature the KEITH® WALKING FLOOR® conveyor system. With the convenience and safety of self-unloading plus an expanded range of backhaul opportunities, Titan Moving Floor and V-Floor® trailers continue to grow in popularity for hauling all kinds of products and materials.

KEITH® RUNNING FLOOR II

Specially designed for lightweight, high volume trailer applications, the KEITH® WALKING FLOOR® conveyor system unloads nearly any material including MSW, green waste, bulk grains, wood products, pallets, drums, bales and rolls.

KEITH® V-FLOOR™

The solid steel “extreme-duty” moving-floor system from KEITH comes through with the ultimate in backhaul versatility.

V-PLOW CLEAN-OUT SYSTEM

Developed with Titan engineering, the V-Plow follows behind fine bulk materials as they are off-loaded by the V-Floor system to ensure that they unload cleanly.

GOING GREEN

Thanks to the fuel efficiency of THINWALL™ trailers, Titan Trailers has been contributing to the “greening” of the transportation industry for many years. With the opening of the new 37,000 square foot addition to our manufacturing facilities, we have taken our commitment to a healthier environment a step further. The new facility, which houses Titan’s R&D operations, Quality Control and Final Finish departments, incorporates several state-of-the-art features for improved health and energy efficiency.

IN-FLOOR HEATING

This system delivers heat at the floor level, where it is needed most, and improves energy efficiency by up to 30%, compared to traditional heating. In old-style systems, much of the heat from ceiling-mounted heaters was wasted as the hot air collected up at the ceiling. Blowing heat to the floor level required expenditure of additional energy. The in-floor heating system maintains even heat from the floor to ceiling, with no waste. Precise temperature controls with integrated floor sensors deliver quick and constant heat recovery. The result is greater comfort for employees with reduced energy consumption.

NATURAL LIGHTING

Visitors immediately notice that the new manufacturing bays are surprisingly bright. See-through overhead doors with southern exposure let our work bays take full advantage of free, natural sunlight.

CONTROLLED ELECTRICAL LIGHTING

Strategically placed light sensors adjust supplemental electrical lights as needed throughout the day. Low energy light fixtures become dimmer as the sun rises, then begin to brighten again later in the afternoon, so our work areas are evenly lit throughout the day.

SOLAR HEAT

The south-facing transparent doors also assist the heating process by delivering free radiant heat to the building. On sunny winter days, natural heat from the sun can warm the shop to about 2º warmer than our thermostat setting, so no energy is needed for our in-floor heating system.

PATENTS